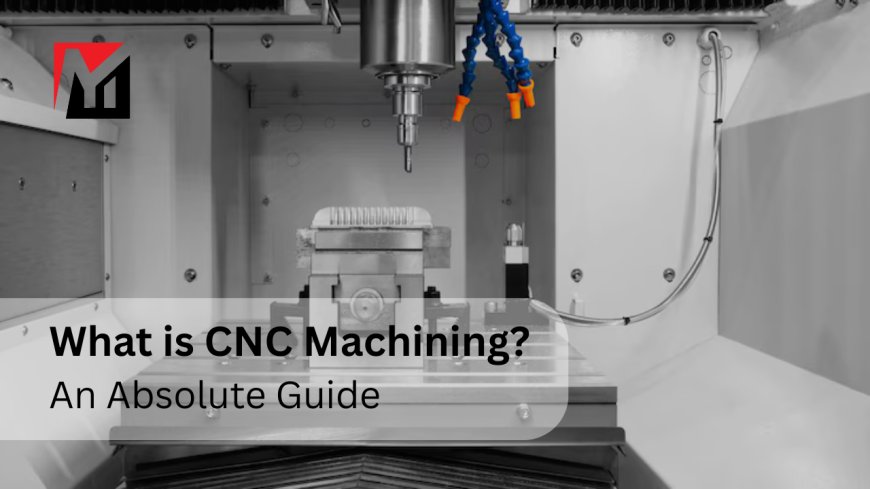

Unlocking Precision and Efficiency: The Role of CNC Machining in Modern Manufacturing

Explore CNC machining, its process, benefits, materials, and applications in modern manufacturing. Discover why CNC machining is vital for precision and efficiency.

In the evolving world of manufacturing, precision and efficiency have become paramount. One technology that has reshaped the landscape is CNC machining. Combining computer-aided design with computer numerical control, CNC machining allows manufacturers to produce complex, high-precision parts with speed and consistency. This process is indispensable across industries such as aerospace, automotive, medical devices, and electronics. This article explores the fundamentals of CNC machining, its benefits, applications, and future prospects.

What Is CNC Machining?

CNC machining, short for Computer Numerical Control machining, is a subtractive manufacturing process where computer-controlled machines remove material from a workpiece to form a final product. The process begins with a digital design created in CAD software, which is then converted into machine-readable code (G-code) that directs the movement of cutting tools.

Unlike manual machining, CNC machining automates the process, ensuring parts are made to exact specifications with minimal human error. Machines operate along multiple axescommonly three to fiveenabling them to cut, drill, and mill intricate shapes that meet stringent tolerance requirements.

The CNC Machining Process

The CNC machining workflow consists of several stages:

1. Design and Programming

Designers create a 3D model of the part using CAD software. This model is converted to G-code through CAM software, which dictates the tool paths, speeds, and cutting depths.

2. Setup

Operators prepare the CNC machine by selecting appropriate cutting tools, securing the raw material (workpiece), and loading the program.

3. Machining

The machine executes the G-code, removing material according to the programmed instructions. This operation is often monitored to ensure quality and to make real-time adjustments if necessary.

Types of CNC Machines

Different CNC machines serve various manufacturing needs:

-

CNC Milling Machines: Use rotating tools to cut the workpiece, suitable for complex shapes and surfaces.

-

CNC Lathes: Rotate the workpiece while cutting tools shape the material, ideal for cylindrical parts.

-

CNC Routers: Typically used for softer materials like wood and plastic.

-

CNC EDM (Electrical Discharge Machines): Use electrical sparks to shape hard metals and complex geometries.

-

CNC Plasma and Laser Cutters: Utilize intense heat to cut through metals and other materials.

Each machine type offers specific capabilities based on the application requirements.

Benefits of CNC Machining

CNC machining offers several advantages that have contributed to its widespread adoption:

Precision and Accuracy

CNC machines can achieve tolerances within 0.001 inches, essential for industries that demand exact specifications, such as aerospace and medical device manufacturing.

Consistency and Repeatability

Once programmed, CNC machines produce parts that are identical across large production runs, ensuring uniform quality.

Speed and Efficiency

Automation reduces production time and labor costs. CNC machines can operate continuously, increasing throughput.

Flexibility

CNC machining accommodates a broad range of materials and design complexities, allowing manufacturers to adapt quickly to changing product demands.

Waste Reduction

Optimized cutting paths and precise control minimize material waste, supporting cost savings and sustainability initiatives.

Materials Suitable for CNC Machining

CNC machining supports a diverse selection of materials:

-

Metals: Aluminum, stainless steel, titanium, brass, copper.

-

Plastics: ABS, PEEK, nylon, Delrin, polycarbonate.

-

Composites: Carbon fiber and fiberglass.

-

Others: Ceramics and wood (typically for prototyping).

The choice of material depends on the products mechanical requirements, environmental conditions, and cost considerations.

Industrial Applications of CNC Machining

CNC machining is crucial in numerous industries:

-

Aerospace: Precision manufacturing of turbine blades, structural components, and engine parts.

-

Automotive: Production of engine components, transmission parts, and custom accessories.

-

Medical: Fabrication of surgical tools, implants, and diagnostic equipment requiring biocompatibility.

-

Electronics: Manufacturing of housings, connectors, and internal components.

-

Oil and Gas: Creation of high-durability valves, fittings, and equipment parts.

Its versatility and precision make CNC machining the backbone of many manufacturing sectors.

CNC Machining Compared to Other Manufacturing Methods

CNC machining offers distinct advantages compared to alternatives:

-

Manual Machining: CNC reduces human error and increases production speed.

-

3D Printing: CNC-machined parts generally have superior strength, surface finish, and material options.

-

Injection Molding: While molding suits high-volume plastic parts, CNC machining is cost-effective for prototyping and metal components.

CNC machining often complements other manufacturing methods to optimize production.

Challenges in CNC Machining

Despite its benefits, CNC machining faces challenges:

-

Initial Investment: The cost of machines and software can be high.

-

Operator Skill: Skilled programmers and operators are essential for optimal use.

-

Tool Maintenance: Cutting tools wear over time and require regular replacement to maintain precision.

These challenges are mitigated through training and preventive maintenance.

The Future of CNC Machining

Technological advancements continue to drive CNC machinings evolution:

-

Automation and AI: AI-driven programming and predictive maintenance enhance efficiency.

-

Smart Factories: Integration with IoT enables real-time monitoring and adaptive control.

-

Hybrid Manufacturing: Combining additive and subtractive processes offers new design possibilities.

-

Sustainability: Efforts focus on eco-friendly materials, energy efficiency, and waste reduction.

These trends ensure CNC machining will remain central to manufacturing innovation.

Conclusion

CNC machining has transformed manufacturing by providing unmatched precision, consistency, and flexibility. Its ability to work with diverse materials and produce complex parts efficiently makes it indispensable across industries. As technology advances, CNC machining will continue to enable manufacturers to meet ever-increasing demands while driving innovation and sustainability.