Warehouse Inventory Tracking and Warehouse Management Inventory Software

At the heart of successful warehouse operations lies warehouse inventory tracking and the use of warehouse management inventory software. These tools are essential for maintaining real-time visibility, improving accuracy, and enhancing operational efficiency across the supply chain.

Understanding Warehouse Inventory Tracking

Warehouse inventory tracking refers to the system or method used to monitor, manage, and account for the movement and storage of goods within a warehouse. It involves tracking every item that enters, is stored, moved, or leaves the facility. The goal is to maintain an accurate record of inventory levels, locations, and statuses to prevent stockouts, overstocking, shrinkage, and misplacement.

Key aspects of inventory tracking include:

-

Barcode Scanning: Most warehouses use barcode technology to scan products at every point of movement. This provides instant updates to the inventory database.

-

RFID Tracking: Radio Frequency Identification (RFID) tags allow for wireless tracking of inventory, which improves speed and reduces manual labor.

-

Serial Number Tracking: High-value or serialized products are tracked using unique identifiers to monitor them individually through their lifecycle.

-

Cycle Counting: A periodic inventory auditing method that verifies inventory accuracy by counting a subset of inventory items.

Proper inventory tracking ensures that businesses can make informed decisions related to purchasing, production planning, and order fulfillment.

What is Warehouse Management Inventory Software?

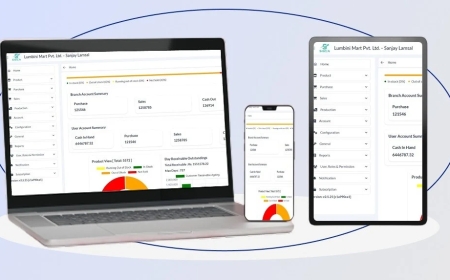

Warehouse Management Inventory Software (WMS) is a specialized solution designed to manage all aspects of warehouse operationsfrom inventory tracking to order picking, shipping, receiving, and more. It serves as the digital brain of a warehouse, enabling seamless coordination between processes, people, and systems.

Modern WMS platforms integrate with Enterprise Resource Planning (ERP) systems, eCommerce platforms, and shipping providers to create a centralized inventory and order management ecosystem.

Core Features of Warehouse Management Inventory Software

-

Inventory Visibility

A WMS provides real-time visibility into stock levels, product locations, and order statuses. This visibility reduces errors, improves order accuracy, and enables better decision-making. -

Automated Replenishment

The software can trigger automatic purchase orders or internal stock transfers when inventory levels fall below a predefined threshold, preventing stockouts. -

Location Management

It helps assign optimal storage locations based on product type, demand frequency, or size, improving picking efficiency. -

Receiving and Putaway

When new stock arrives, the WMS guides warehouse staff on where to place the items for optimal storage and retrieval. -

Order Picking and Packing

The software supports various picking strategies such as FIFO (First-In, First-Out), LIFO (Last-In, First-Out), batch picking, and wave picking to boost efficiency. -

Shipping and Dispatching

Integration with shipping carriers allows for label printing, tracking number generation, and dispatch scheduling from within the software. -

Analytics and Reporting

WMS platforms generate insightful reports on inventory turnover, order accuracy, storage utilization, and employee performance.

Benefits of Using Warehouse Inventory Tracking and Management Software

1. Enhanced Accuracy

Manual inventory tracking is prone to human error. Software-driven tracking drastically reduces errors, ensuring that whats on paper matches what's in the warehouse.

2. Improved Efficiency

Automating repetitive tasks like data entry, reordering, and picking instructions speeds up operations and frees employees for more strategic work.

3. Cost Reduction

Better inventory control reduces the costs associated with overstocking, stockouts, and obsolescence. It also minimizes the need for physical audits and administrative overhead.

4. Faster Order Fulfillment

Efficient picking, packing, and shipping workflows lead to faster order processing, improving customer satisfaction and enabling businesses to meet same-day or next-day delivery expectations.

5. Scalability

Whether a business manages a single small warehouse or a complex network of distribution centers, warehouse management software can scale to match operational growth.

6. Regulatory Compliance

For industries such as pharmaceuticals, food, or electronics, where regulatory compliance is essential, WMS helps maintain detailed records for traceability and auditing purposes.

Choosing the Right WMS for Your Business

When selecting a warehouse management inventory software, consider the following factors:

-

Cloud vs. On-Premise: Cloud-based solutions offer flexibility, easy updates, and remote access, whereas on-premise systems may offer more control and security for certain industries.

-

Integration Capabilities: Ensure the WMS integrates with your existing ERP, eCommerce platforms, and logistics providers.

-

Ease of Use: The user interface should be intuitive, allowing quick onboarding of staff.

-

Customization: A good WMS should be customizable to adapt to your specific workflow, inventory types, and business model.

-

Support and Training: Choose a vendor that offers robust customer support, onboarding, and ongoing training resources.

Latest Trends in Warehouse Inventory Management

-

AI and Machine Learning

AI is increasingly being used in WMS to predict demand, optimize inventory levels, and identify inefficiencies. -

Robotics and Automation

Automated guided vehicles (AGVs) and robotic picking systems are transforming warehouse operations, reducing dependency on manual labor. -

IoT Integration

Internet of Things (IoT) sensors and smart devices provide real-time data on product conditions (like temperature), asset movement, and equipment health. -

Mobile WMS

Mobile-friendly WMS apps allow staff to perform tasks from handheld devices, increasing mobility and responsiveness on the warehouse floor. -

Sustainability Features

Modern WMS includes tools to reduce energy use, optimize packaging, and minimize waste, aligning operations with environmental goals.

Conclusion

Warehouse inventory tracking and warehouse management inventory software are indispensable tools for any business that stores, moves, or ships physical products. As supply chains become more complex and customer expectations rise, companies must leverage modern inventory tracking systems and robust WMS solutions to remain competitive. By implementing the right technology, businesses can achieve greater accuracy, faster fulfillment, lower costs, and a stronger bottom line.

Whether you're a small business managing a single facility or a large enterprise overseeing multiple warehouses, investing in a scalable, feature-rich WMS will position you for long-term success in an increasingly digital supply chain environment.