CNC Machining Service: Precision Manufacturing for High-Quality Parts

Explore Elitemold Tech’s CNC Machining Service—precision parts, fast turnaround, and expert support for all your prototyping and production needs.

When it comes to delivering consistent, tight-tolerance components with short lead times, few methods are as reliable as a professionalCNC Machining Service. Businesses across industriesfrom aerospace to medical devicestrust CNC machining to turn digital designs into real-world components with pinpoint accuracy.

Whether you're working with metal, plastic, or exotic materials, CNC machining offers unmatched precision, repeatability, and efficiency in modern manufacturing.

What Is CNC Machining?

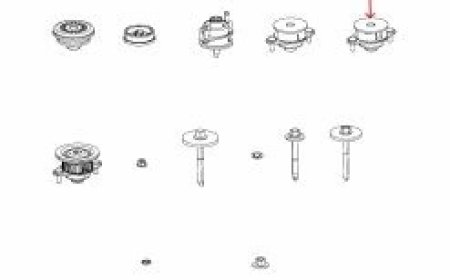

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed software controls the movement of factory tools and machinery. The process involves:

-

Turning (for cylindrical parts)

-

Milling (for complex surfaces and cavities)

-

Drilling

-

Tapping

-

Surface finishing

Machines follow exact design instructions, transforming CAD models into precise, functional parts. Its widely used in prototyping, tooling, and full-scale production due to its scalability and reliability.

Key Benefits of CNC Machining Service

1. High Precision and Consistency

With tolerance capabilities as tight as 0.005 mm, CNC machining ensures every part matches the specifications. This is critical in industries where reliability and safety are non-negotiable, such as automotive and aerospace.

2. Broad Material Compatibility

CNC machining supports a wide range of materials including:

-

Metals: Aluminum, stainless steel, titanium, brass, copper

-

Plastics: ABS, nylon, PEEK, Delrin

-

Composites and specialty alloys

This flexibility allows engineers to match performance and cost requirements without switching production methods.

3. Speed and Efficiency

Modern CNC systems operate with high spindle speeds and automated tool changes, enabling fast turnaround without compromising accuracy. Rapid production makes it ideal for both prototyping and short to medium production runs.

4. Design Complexity

Multi-axis CNC machines (3-, 4-, and 5-axis) allow intricate geometries, undercuts, and fine details to be machined in a single setupsaving time and minimizing errors.

5. Repeatability

Once a program is developed and validated, it can be used indefinitely, ensuring every subsequent part maintains the same dimensions and performance. This makes CNC machining ideal for producing high volumes of identical components.

Common Applications Across Industries

Aerospace

From turbine housings to landing gear components, CNC machining meets the aerospace industry's rigorous standards for strength, weight, and heat resistance.

Medical Devices

CNC machining is used to manufacture surgical instruments, implants, and diagnostic devices from biocompatible metals and plastics. Precision is critical for safety and function.

Automotive

Engine parts, transmission components, and custom brackets are often produced through CNC processes for optimal fit, finish, and durability.

Robotics and Automation

Complex housings, joints, and connectors for robotic arms and automation systems require exact tolerances that CNC machining readily delivers.

Industrial Machinery

Large gears, shafts, and mechanical enclosures are machined to withstand continuous, heavy-duty operation.

How CNC Machining Works

Step 1: CAD Design

Engineers create a 3D CAD model of the part, which defines every surface, hole, and edge. These files serve as the blueprint for machining.

Step 2: CAM Programming

The CAD model is imported into CAM (Computer-Aided Manufacturing) software, which generates toolpaths and G-codethe language CNC machines use to perform movements.

Step 3: Material Selection

Materials are chosen based on part function, cost, weight, and strength requirements. Most services maintain a wide inventory of metals and plastics.

Step 4: Setup and Machining

The raw material (workpiece) is loaded onto the machine. Automated tool changers, coolant systems, and sensors ensure efficient, consistent machining.

Step 5: Inspection and Quality Control

After machining, parts undergo dimensional checks using CMMs (Coordinate Measuring Machines), micrometers, or laser scanners to verify compliance with specifications.

Why Choose Elitemold Tech for CNC Machining?

At Elitemold Tech, we provide high-precision CNC machining services backed by advanced equipment, experienced technicians, and strict quality protocols. Whether you need one prototype or thousands of production units, we offer:

-

3-, 4-, and 5-axis machining centers

-

Wide material selection

-

DFM feedback for improved manufacturability

-

Quick lead times and on-time delivery

-

ISO-compliant quality management

Our focus is on delivering parts that meet your performance, aesthetic, and regulatory expectationsevery time.

Materials We Work With

We handle a broad spectrum of materials suitable for engineering, functional testing, or end-use applications:

Metals:

-

Aluminum (6061, 7075, etc.)

-

Stainless steel (303, 304, 316)

-

Titanium

-

Tool steels

Plastics:

-

ABS

-

Nylon (PA6, PA66)

-

PEEK

-

Delrin (Acetal)

-

Polycarbonate

Composites and Alloys:

-

Carbon-fiber reinforced polymers

-

Inconel

-

Brass and bronze

Each material is handled with appropriate tooling and feeds to maintain integrity and dimensional accuracy.

Surface Finishes Available

To meet functional and visual requirements, Elitemold Tech offers several surface treatments:

-

Anodizing (Type II and Type III)

-

Powder coating

-

Bead blasting

-

Electropolishing

-

Nickel plating

-

Painting

These finishes enhance corrosion resistance, wear protection, and cosmetic appeal depending on your part's application.

Use Cases for CNC Machining Services

-

Rapid prototyping: Turn concepts into real, functional models fast

-

Production tooling: Jigs, fixtures, and dies for assembly or molding lines

-

End-use parts: Industrial components, enclosures, connectors

-

Reverse engineering: Recreate legacy parts with updated specs

-

Short-run manufacturing: Ideal for market testing or bridging production gaps

Get Started with Elitemold Tech

From the first CAD file to the final part, our CNC machining service is designed to save you time, reduce costs, and ensure exceptional quality. Our expert engineers review every design to ensure the process is optimized, reducing waste and avoiding delays.

With Elitemold Tech, you get:

-

Dedicated support

-

Clear timelines

-

Competitive pricing

-

Scalable production

Request a quote today and experience the reliability of a world-class CNC machining partner.