Fruit and Vegetable Processing Market: Innovations, Trends, and Forecast Growth to 2033

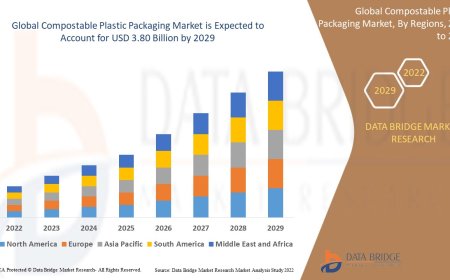

Data Bridge Market Research analyses that the global fruit - vegetable processing market is growing at a CAGR of 7.95% in the forecast period of 2022-2029.

Introduction

The fruit and vegetable processing market plays a critical role in global food systems by extending shelf life, enhancing convenience, and reducing food waste. Processing involves a wide range of techniquesfrom cleaning, cutting, drying, freezing, and canning to juice extraction, pureeing, and packaging. With the growing demand for ready-to-eat (RTE) and convenience foods, this market continues to expand across developed and emerging regions alike. This article explores the growth factors, market dynamics, technology trends, and future outlook of the fruit and vegetable processing market through 2033.

Market Overview

The globalfruit and vegetable processing marketwas valued at approximately USD 300 billion in 2024 and is projected to reach USD 470 billion by 2033, expanding at a compound annual growth rate (CAGR) of 5.2%. Growth is being driven by changing dietary patterns, increasing urbanization, a rise in demand for healthy processed foods, and advancements in food preservation technologies.

Key Market Drivers

-

Rising demand for convenience and ready-to-cook foods

-

Increasing global population and urbanization leading to higher food consumption

-

Technological advancements in food preservation and packaging

-

Growing awareness of food safety and hygiene

-

Shift toward plant-based diets and clean-label products

Processing Techniques

-

Fresh-cut processing including washing, peeling, cutting, and packaging of raw produce

-

Canning involving heat treatment and vacuum sealing in metal or glass containers

-

Freezing which locks in nutrition and extends shelf life without added preservatives

-

Drying and dehydration removing moisture content to increase storage stability

-

Juicing and pureeing converting raw produce into beverages, pastes, and pulps

-

Fermentation for products like pickles, kimchi, and sauerkraut

By Product Type

-

Fruits including apples, bananas, berries, mangoes, and citrus

-

Vegetables including carrots, spinach, tomatoes, onions, and potatoes

By Processing Equipment

-

Pre-processing equipment such as washers, cutters, and peelers

-

Processing equipment including dryers, pasteurizers, and evaporators

-

Packaging equipment for sealing, labeling, and sorting finished products

By Operation Type

-

Automatic processing systems for high-volume commercial food production

-

Semi-automatic systems suitable for mid-sized manufacturers

-

Manual operations common in small-scale or local processing units

By Application

-

Snacks including dried fruit chips and vegetable crisps

-

Juices and beverages like smoothies, cold-pressed juices, and fruit concentrates

-

Soups and sauces made from processed tomatoes, pumpkins, and onions

-

Ready-to-eat meals including frozen vegetable mixes and pre-cut salad kits

-

Canned goods like corn, peas, peaches, and mixed fruits

Regional Insights

-

North America driven by strong consumer demand for organic and convenience foods

-

Europe emphasizing clean-label and sustainable food processing practices

-

Asia-Pacific leading in production due to large agricultural base and rising middle class

-

Latin America increasing investments in food export processing facilities

-

Middle East and Africa improving food preservation methods to combat perishability

Technological Trends

-

Cold plasma technology for microbial control without heat damage

-

High-pressure processing (HPP) for extended shelf life while retaining nutrients

-

Robotics and automation in sorting, peeling, and packaging processes

-

Smart sensors and IoT in monitoring processing lines for quality control

-

Blockchain and traceability tech to ensure food origin and safety compliance

Challenges

-

High capital investment for setting up processing facilities

-

Stringent regulations regarding food safety, additives, and labeling

-

Seasonal dependency of raw materials affecting supply chain stability

-

Balancing nutritional retention with extended shelf life

-

Managing energy and water consumption in processing plants

Competitive Landscape

-

Nestl focusing on frozen and canned vegetable products

-

Dole Food Company leading in processed fruits and juices

-

Conagra Brands offering a wide range of RTE vegetable meals

-

Kraft Heinz producing fruit-based sauces and packaged vegetables

-

JBT Corporation providing processing and packaging equipment to the industry

Future Outlook (20252033)

-

Increased use of AI and automation in processing plants

-

Greater demand for eco-friendly packaging and zero-waste operations

-

Expansion of e-commerce boosting packaged produce sales

-

Growth in exports from Asia and Latin America to global markets

-

Rising focus on nutrient-dense, plant-based processed snacks and meals

Source:https://www.databridgemarketresearch.com/reports/global-fruit-vegetable-processing-market

Conclusion

The fruit and vegetable processing market is poised for steady growth as it aligns with global trends in health, sustainability, and convenience. With advancements in technology, packaging, and cold chain logistics, the market will continue to evolve to meet consumer needs. Stakeholders investing in innovation, clean-label production, and automation will be best positioned to capitalize on the growing demand for processed fruit and vegetable products through 2033.