Hexane Manufacturing Plant Project Report – Strategic Insights by Procurement Resource

Procurement Resource, a global leader in market intelligence and cost modeling, proudly presents its in-depth Hexane Manufacturing Plant Project Report.

Procurement Resource, a global leader in market intelligence and cost modeling, proudly presents its in-depth Hexane Manufacturing Plant Project Report. This detailed report provides entrepreneurs, investors, and industrial stakeholders with comprehensive technical, financial, and strategic insights into setting up a successful hexane manufacturing facility. From market dynamics to plant infrastructure, production processes, and return on investment, the report is designed to support profitable and sustainable decision-making.

Hexane: A Versatile Industrial Solvent

Hexane (C?H??) is a straight-chain alkane hydrocarbon, widely used across multiple industries due to its strong solvent properties, volatility, and cost-effectiveness. Hexane exists as a colorless liquid with a low boiling point and is primarily derived as a by-product of crude oil refining.

Key Applications of Hexane:

- Edible oil extraction from seeds (soybean, sunflower, canola)

- Industrial solvent in adhesives, glues, paints, and cleaning agents

- Pharmaceutical and chemical synthesis

- Polymerization processes

- Laboratory reagents and chromatography

Due to its effectiveness in separating oil from plant materials and its role in chemical processes, hexane remains a critical industrial input across agriculture, petrochemicals, pharmaceuticals, and food processing.

Comprehensive Guide to Setting Up a Hexane Manufacturing Plant

The Hexane Manufacturing Plant Project Report by Procurement Resource offers an exhaustive roadmap covering every operational, technical, and financial consideration required for plant setup and management. The report is built for investors seeking market entry and for enterprises aiming to expand or modernize their solvent production facilities.

1. Market Overview and Demand Outlook

The report starts with a deep dive into the global hexane market, analyzing:

- Supply-demand trends across regions

- Industry segmentation by application

- Price fluctuations of feedstock and end-product

- Trade flows and major exporting/importing nations

- Regulatory considerations (especially food-grade hexane)

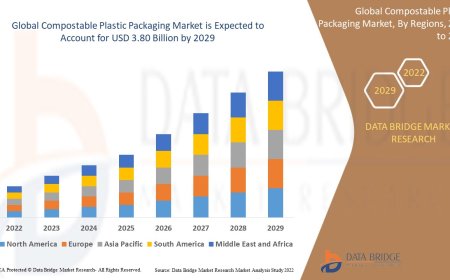

Asia-Pacific leads global hexane consumption, driven by the booming edible oil sector in countries like India and China. North America and Europe, meanwhile, show consistent demand in the chemical and pharmaceutical sectors. The market is also impacted by growing concerns over environmental regulations and a shift toward safer solvent alternatives in some applications.

2. Manufacturing Process Overview

Hexane is typically produced as a fractional distillation product from petroleum or natural gas condensates. The report outlines a detailed step-by-step manufacturing process:

Standard Hexane Production Process:

- Feedstock Selection: Light naphtha from petroleum refining is used as the primary raw material.

- Fractional Distillation: Naphtha is fed into a fractionating column and subjected to thermal separation under controlled pressure and temperature to extract the C6 hydrocarbon range.

- Hydrogenation and Isomerization (optional): These processes may be used to enhance the purity or modify the hexane isomer mix (n-hexane, isohexanes).

- Purification and Drying: Further purification involves removal of sulfur compounds, aromatics, and moisture using drying agents and adsorbents (e.g., molecular sieves).

- Storage and Packaging: Final product is stored in closed-loop, vapor-controlled tanks and packaged in drums or tanker containers.

Food-grade hexane requires additional filtration and quality control steps to meet FDA or EU purity standards.

3. Equipment and Machinery Requirements

Setting up a hexane production plant requires investment in specialized equipment, typically designed for high-pressure, volatile hydrocarbon handling. The report includes specifications for:

- Fractional distillation columns

- Heat exchangers and condensers

- Hydrogenation reactors (if required)

- Molecular sieve or silica-based purification units

- Storage tanks (with vapor recovery systems)

- Flame-proof pumps, pipelines, and valves

- Gas detectors and fire safety equipment

- Automation systems and control panels

The report also compares manual, semi-automated, and fully automated setups to guide capital investment according to production capacity and operational efficiency goals.

4. Infrastructure and Utility Requirements

A hexane manufacturing plant demands carefully planned infrastructure for safety, efficiency, and environmental compliance.

Key Infrastructure Needs:

- Land area: Between 10,000 to 25,000 square meters, depending on capacity and storage

- Power: High voltage electricity for thermal and mechanical operations

- Water: For cooling systems and cleaning

- Steam and fuel: For distillation processes

- Safety systems: Fire suppression systems, gas leak detectors, and explosion-proof environments

- Effluent Treatment: Systems for controlling and disposing of chemical wastewater

Workforce Needs:

- Process engineers and plant operators

- Safety and quality control personnel

- Logistics, maintenance, and admin staff

5. Financial Analysis and Project Viability

A central focus of the report is a robust financial feasibility study covering capital and operating costs, revenue projections, and profitability metrics.

Capital Investment (CAPEX):

- Land and infrastructure development

- Equipment and machinery acquisition

- Installation, commissioning, and safety systems

- Licensing and regulatory compliance costs

Operating Costs (OPEX):

- Feedstock procurement (naphtha or natural gas liquids)

- Labor and utilities

- Maintenance and repair

- Packaging and distribution

- Environmental monitoring and compliance

Economic Indicators:

- Break-even point and payback period

- Return on Investment (ROI)

- Internal Rate of Return (IRR)

- Net Present Value (NPV)

- Sensitivity analysis (feedstock price variation, demand shifts)

Sustainability and Regulatory Trends

As environmental concerns around volatile organic compounds (VOCs) grow, hexane use is under increasing regulatory scrutiny, particularly in food applications. The report highlights:

- Shift toward green extraction solvents in food and pharma

- Development of low-hexane-loss processes

- Use of closed-loop solvent recovery systems to minimize emissions

- Regulations from bodies like OSHA, EPA, REACH, and FDA

Despite these challenges, hexane continues to be economically irreplaceable in several industrial processes. Innovations in solvent recycling and process containment are helping to extend its viability in environmentally conscious markets.

Why Choose Procurement Resource?

Procurement Resource combines engineering precision with market intelligence to deliver highly actionable project reports. Our team of chemical engineers, cost analysts, and market strategists provides tailored insights that reduce risks and enhance profitability for your manufacturing venture.

Our expertise includes:

- Cost modeling and real-time price tracking

- Supply chain benchmarking

- Production process optimization

- Financial forecasting and investor readiness

- Customized feasibility and pre-investment reports

Whether you are a startup exploring market entry or an established player seeking to expand, our reports help you plan, build, and scale with confidence.

Request a Free Sample Report Today

Looking to launch a Hexane Manufacturing Plant?

Gain access to a complete strategic blueprinttechnical process, cost analysis, market trends, and investment outlook.

Request Free Sample Report - https://www.procurementresource.com/reports/hexane-manufacturing-plant-project-report/request-sample

Contact Information

Company Name: Procurement Resource

Contact Person: Ashish Sharma (Sales Representative)

Email: sales@procurementresource.com

Location: 30 North Gould Street, Sheridan, WY 82801, USA

Phone Numbers:

UK: +44 7537171117

USA: +1 307 363 1045

Asia-Pacific (APAC): +91 1203185500